Tyres are a consumable item, and at some point they will need to be replaced. It’s easy to bring the motorcycle to a shop to replace your old tyres, but then you would be missing out on a great opportunity to pull out your tool kit and practice a skill that at some point you’ll need.

Flat tyres can happen anywhere, and carrying the tools to fix a flat is only half of being prepared. The other half is having experience using the tools.

Touratech’s Eric Archambault provides some tips on motorcycle maintenance, and shows you how to change a tyre.

The Tools You’ll Need:

-

- Tyre levers

- Valve Stem Fishing Tool

- Tyre Pressure Gauge

Step One: Removing the wheel

The actual process of removing the wheel varies a little from motorcycle to motorcycle, so check your owners manual. Make note of any spacers, bushings, or cush-drive pieces to ensure they go back in the proper position when reinstalling the wheel.

Step Two: Prepare the wheel for tyre removal

Remove the valve core from the valve stem (this will quickly deflate the tyre), remove the valve stem retaining nut (normally with a 12mm wrench), back the bead lock retaining nut all the way out. I like to also take a quick minute at this point and wipe down the rim with a rag, as I prefer working with clean parts.

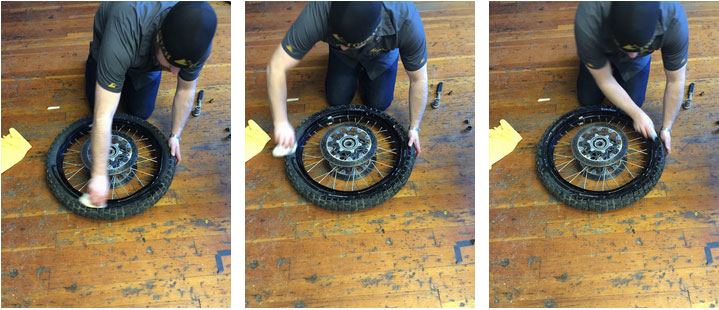

Step Three: Break the bead

There are many methods to break the bead. If I am not using a tyre machine, I find the side-stand method works the best: Lay the wheel flat on the ground, then use the side-stand to put pressure as close to the rim as possible. It may take a few applications on different spots to get the bead to break loose. You will know when the bead is broken as the tyre will fall into the centre trough of the rim.

Step Four: Lube the tyre

I like to use a little dish soap with water to lube the tyre and allow the tyre to slide over the rim and tyre irons a bit easier. This step isn’t total necessary, but I find it makes the job easier. In the field I will normally just use water. With the rag, wipe from the bead up the sidewall a little way.

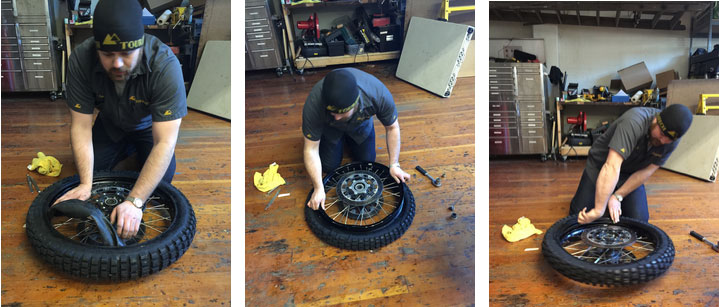

Step Five: First Bead

If the wheel has a bead-lock, start with a tyre iron on either side of the bead-lock, then you will work towards the valve stem. If you do not have a bead-lock, just start straddling the valve stem.

You will want to ensure the tyre is in the center trough across from where you are starting with the tyre irons, as this will give the slack needed to pull the tyre over the rim. Kneeling on the tyre can help with this.

Now, with the first part of the bead over the rim, remove one tyre iron and start working around the rim. Moving a few inches between levering points will work better than trying to lift large sections over the rim.

Step Six: Remove the tube

With one bead dismounted, remove the tube. If this is a field repair of a flat, inspect the tube and see where the puncture happened. If the puncture is on the side of the tube, chances are it was a pinch flat from running low tyre pressure, and the tube was pinched between the ground and the rim.

If the puncture is elsewhere, the tyre should be checked to make sure the cause for the puncture is not still lodged in the tyre. If only the tube is being replaced, you can skip to step 10.

Step Seven: Remove the second bead, remove the tyre

There are two different methods to remove the second bead from the wheel. The first method works well if dealing with bead-locks, while the second method is more versatile and works better for smaller diameter wheels.

1. Using the same procedure from step five, dismount the second bead. Once the tyre is loose around the rim, drop the rim into the centre of the tyre and pull it free. This might take a little work with a tyre iron to fully free the tyre.

2. Working from the same side of the wheel that already has a bead removed, reach your two tyre irons under both beads and work a 6”-8” section of bead over the wheel. Now brace the wheel with your foot, and pull the tyre the rest of the way off.

Step Eight: Inspect the wheel

With the tyre removed, ensure the rim-strip is intact (tube type and KTM tubeless only). In the case of a tube type tyre, a few wraps of duct tape can be used to replace a broken or damaged rim-strip. Check the rim for burrs or other damage. If the rim has burrs, file or stone them down; if the rim is cracked it is due for replacement.

Step Nine: Remounting the tyre

Lube the tyre in the same manner as during removal. Lay the tyre on the ground, place the wheel on top of it (with the bead-lock inside the tyre if so equipped), and get the first bead over the rim. This might take a tyre iron to assist in the process, though sometimes the wheel can be pressed onto the wheel.

Once the first bead is on the wheel, insert the tube. I prefer to use a valve stem fishing tool to make this easier. Load the nut for the valve stem over the cable of the fishing tool before running it through the hole and threading it into the valve stem.

Stuff the tube into the tyre. It is best to have a little air in the tube to prevent it from getting twisted.

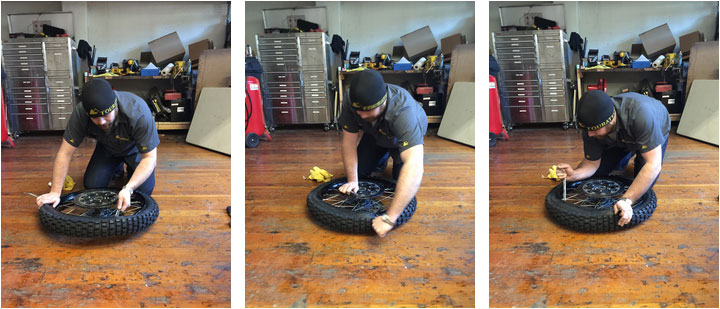

Step Ten: Second bead

Now that one bead is on the wheel and the tube is installed (if required), it is time to get the second bead mounted. If a bead-lock is present, start in the same fashion as during removal: with a tyre iron on either side of the bead lock.

Once that first part of the bead is over the rim, start working one tyre iron around the bead. Be careful not to pinch the tube during this process – if you do not bring the tyre iron past perpendicular to the rim this will help prevent pinching. Keep the mounted part of the tyre inside the centre trough of the rim and slowly, a few inches at a time, work around the tyre.

Once the second bead is mounted, fill the tyre with air. It can take 30-40 psi to get the bead to fully seat. Don’t be afraid to air the tyre up past what you are running as it is easy to air it back down. Once the tyre is at pressure, I like to hold my ear to the sidewall and see if I can hear a leak. At this point tighten down the nut for the valve stem and bead-lock.

Step Eleven: Reinstall the wheel

Making sure all of the spacers are back where they belong, get the wheel back in place and tighten everything down. Using a flathead screwdriver to spread brake pads in the calipers can make this task easier.

Make sure to pump the brakes before riding again, as chances are the pads have been pushed in a bit and will not give the instant response you will be expecting.

Additional tips and tricks:

If you are in the field dealing with a flat you pretty much have to play the hand you are given. A tyre changing mat can give you a clean place to change a tyre in the middle of nowhere, keeping your bearing out of the dirt. I will normally use my jacket for a field repair if I do not have a changing mat.

For a tyre change in the garage, bring the new tyre into the house to warm it up over night if it is cold outside, as this will make it softer and more pliable. On the same note, taking the motorcycle for a quick spin to get heat into the tyres will also aid in getting the mounted tyres off.

If you don’t want to work on the floor, galvanised rubbish bins work wheel as a wheel stand.

About the Author:

Eric is an incurable motorcycle nut. He’s owned everything from scooters to vintage motocross bikes and now spends much of his time riding and talking about adventure motorcycles.

Recent Comments